Guidance on safety and standards offer clarity for maritime batteries to charge ahead

Battery technology is widespread, and its use continues to grow strongly in power systems for new ships. Recent advancements in safety regulations and standardization hold the key to reviving the retrofit market, says Shaun White, Managing Director of Foreship UK (MBF Member)

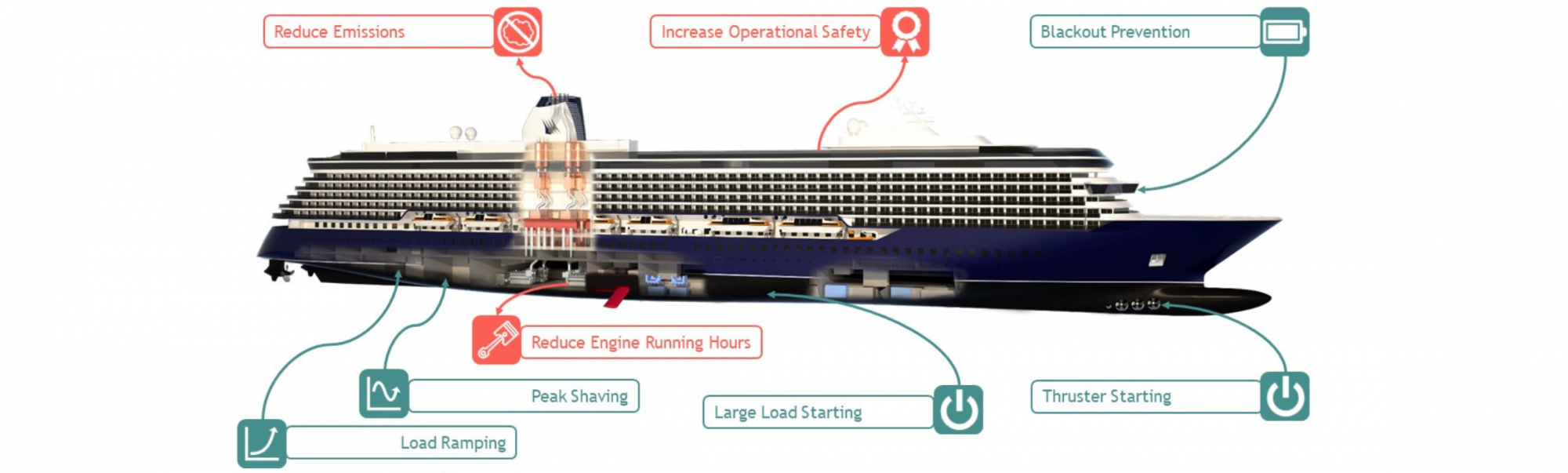

Photo Credit - Foreship UK

The latest figures from the Maritime Battery Forum (MBF) show the number of ships featuring battery technology is still climbing but the growth of retrofit projects have fallen. By the end of 2023, MBF reported 1054 seagoing vessels included batteries as part of their power systems, with a combined output of 883 MWh. But, while retrofits and newbuild projects followed a similar growth path to 2019, by last year retrofits contributed only 24% of installations. In 2023 itself, the retrofit share fell further to 11% (29 ships) of 240 battery projects.

MBF indicates that shipowners and forum members attributed the retrofit slowdown in part to COVID-19, with increasing capital equipment costs, high installation expenses, and safety worries also cited.

These obstacles, combined with the ongoing challenge of locating appropriate space for batteries on current vessels, led many owners to postpone or put off investments in battery technology.

MBF also believes steps which aim to simplify installations and create a safety framework for the maritime battery sector can help overcome key points of owner concerns about battery retrofits.

Battery recharge

Shaun White, the Managing Director of Foreship (UK), has been a strong supporter of maritime battery systems for a long time. He emphasizes the important role advancing safety measures and establishing standards can play in addressing misconceptions that have hindered the recognized benefits of installing shipboard energy storage solutions.

“The maritime battery is often misunderstood, with many believing that a sizable battery is necessary for environmental and operational advantages, leading to cost, space, and safety concerns. Consequently, proposals for projects face difficulties in obtaining necessary approvals and moving forward with implementation.”

The maritime battery retrofit market is caught in an ongoing cycle where the price point does not decrease because of limited adoption, and limited adoption persists due to the high price point.

Foreship collaborates with owners on battery projects continuously, covering everything from feasibility studies, and detailed design to installation supervision. Doing so has involved working ahead of regulations to make battery systems safer, more dependable, and better designed, says White.